Film/Sheet Plastic Recycling Shredder

This Film/Sheet Plastic Recycling Shredder is suitable for grinding various soft and hard edge materials with a thickness of 0.02~5MM, such as PP/PE/PVC/PS/GPPS/PMMA films, sheets, and plates used in stationery, packaging, and other industries.

It can be used to collect, crush and convey the edge materials produced by extruders, laminators, sheet machines, and plate machines. The crushed materials are then transported by a conveying fan through a pipeline to a cyclone separator, and then pushed into the extruder screw feed port by a feeding screw for automatic mixing with new materials, thus achieving instant environmental protection and utilization.

Description:

★ Zero waste, 30-second hot crushing and utilization, using sprue material as new material.

★ For extrusion machines used in processes such as film blowing, adhesive tape production, flat yarn production, sheet production, and plate production, it is common to generate both qualified products and edge trim waste during normal operation.

★ While generating edge trim waste, it is important to keep it clean and dry. The clean and dry edge trim waste can be immediately fed into a edge trim shredder for crushing. The crushed edge trim particles are then synchronously and immediately fed into the extrusion machine’s feeding inlet. The crushed particles are proportionally mixed with fresh raw materials, fed into the screw barrel, and extruded to produce high-quality products for recycling and reuse.

★ By synchronously and 100% recycling the edge trim waste, the materials are not exposed to oxidation or moisture contamination (due to steam). This prevents any negative impact on the extruded products, such as compromised strength, stress, or loss of color and gloss. As a result, the quality of the products can be improved. Recycling the edge trim waste in a clean and controlled manner ensures the integrity and quality of the final products.

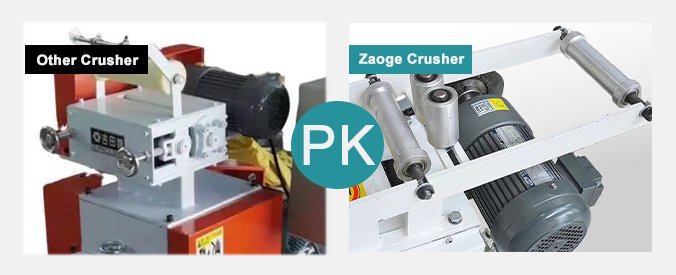

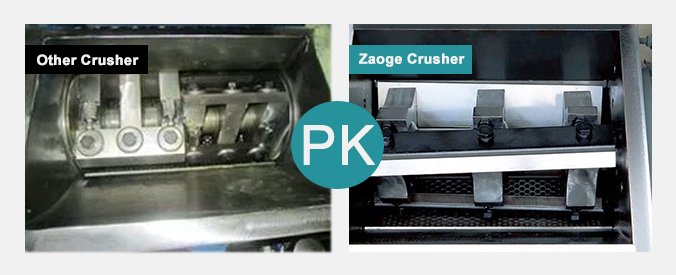

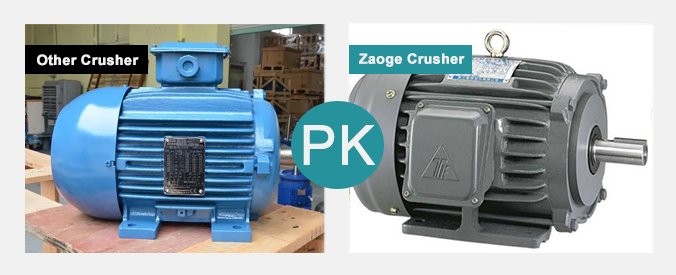

Material Comparison

Good quality comes from every detail

Film/Sheet Plastic Shredder · Feeding Method

The dual-direction traction wheels, after dynamic balance treatment, ensure a smoother and more stable feeding process, reducing the risk of breakage and ensuring a seamless operation.

Film/Sheet Plastic Shredder · Imported Blade Material

Imported NACHI blade material undergoes CNC precision processing, cold and heat treatment, ensuring the accuracy of the tool, improving its wear resistance and sharpness. This increases the tool’s lifespan by 2-3 times.

Film/Sheet Plastic Shredder · Transmission Control

Branded Transmission Motor, Greater Torque, Smooth and Trouble-Free Operation

Film/Sheet Plastic Recycling Shredder· Electric Control

Utilizing Siemens/Taiwan Dongyuan Electrical Components, Enhanced Convenience, Stable Operation, Higher Safety, Extended Lifespan.

Plastic Shredder Applications

Your recycling needs, Our grinding solutions.

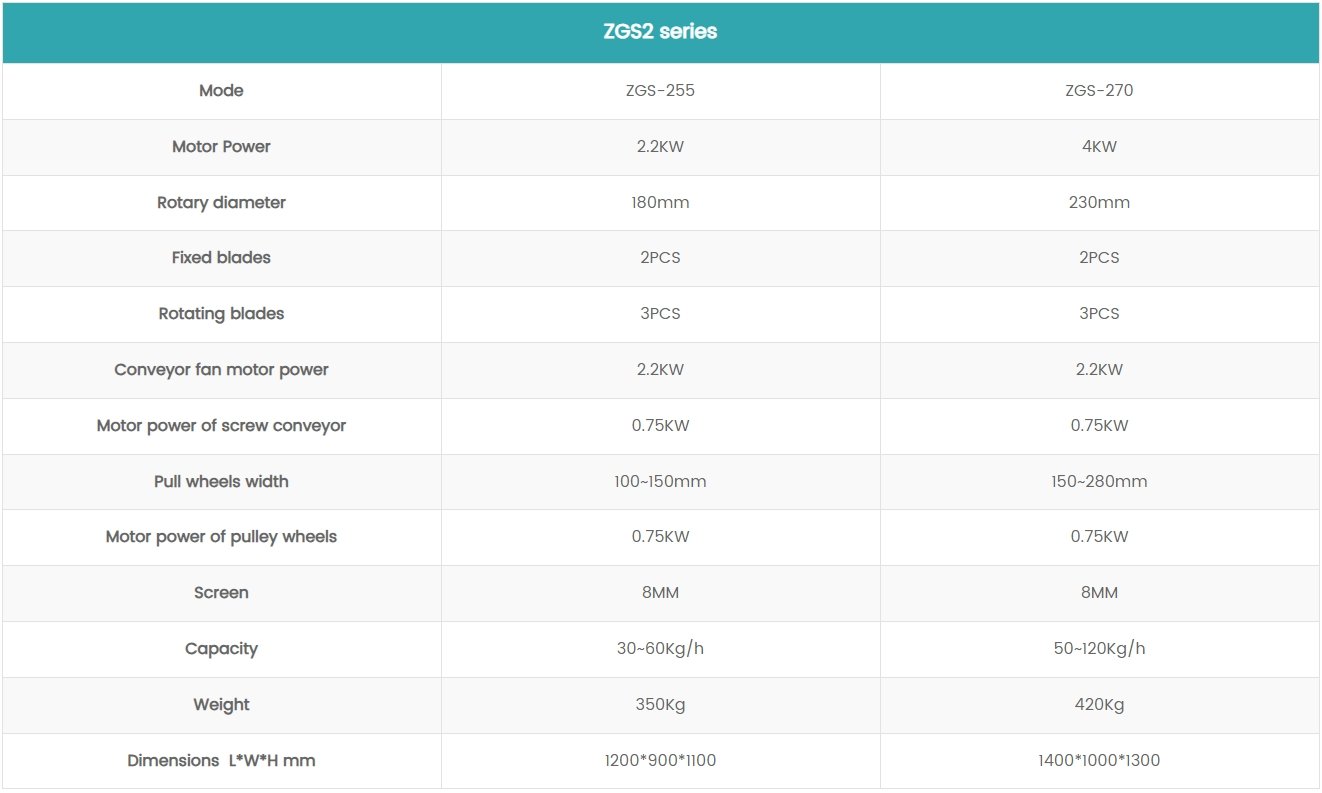

Specifications

Customers Verification

Verification of the creation of letters witnessed by many customers Durable

more than 50% compared to the same period, saving effort and money.

Related Products

Leave Your Message

ZAOGE Crusher

ZAOGE Crusher originated from Taiwan Wan Meng Machinery established in 1977, has always adhered to the service principle of listening to customer voices, meeting customer needs, and surpassing customer expectations. We continuously innovate in technology and management, actively participate in industry competition and cooperation, and have been highly recognized by customers through long-term market experience at home and abroad.

Our main products include plastic shredders, Film Plastic Recycling Shredders, Sheet Plastic Recycling Shredders, Plastic Recycling Shredder machines, Recycling Shredder machines, and Plastic Shredder machines.

—-Help traditional industrial production with low-carbon environmental protection, energy saving, and profit.