-

Power Cord Plug Plastic Shredder

-

Household Plastic Shredder

-

Electronic Appliance Plastic Shredder

-

Film/Sheet Plastic Shredder

-

Powerful Plastic Crusher

PVC/TPU Power Cord Plug

Plastic Shredder

The PVC/TPU Power Cord Plug Plastic Recycling Shredder Machine is designed for crushing soft sprue materials like halogen-free, PVC, PP, PE, TPR, ensuring efficient recycling. The machine offers a versatile solution for processing various types of plastic materials, contributing to environmentally friendly practices and resource conservation. With its robust design, it provides reliable performance for the effective recycling of plastic cables and other materials.

zero waste

noise-free

Easy to clean

long lifespan

PP/PE Household Plastic

Recycling Shredder

The Household Plastic Recycling Shredder excels in grinding tough sprue materials, including PP, PE, and nylon. Its robust design ensures effective recycling, making it a versatile solution for processing various challenging plastic materials. This shredder contributes to sustainable practices by efficiently repurposing materials, showcasing its reliability and effectiveness in recycling processes.

zero waste

low noise

easy maintenance

Easy to clean

ABS/PC Electronic Appliance

Plastic Shredder

The ABS/PC Electronic Appliance Plastic Recycling Shredder Machine is designed for crushing robust nozzle materials like ABS, PC, PMMA, ensuring effective recycling. With its specialized capabilities, this machine offers a reliable solution for processing hard plastic materials, contributing to sustainable practices and resource conservation. Its sturdy construction ensures durability and efficiency in the recycling of ABS, PC, PMMA, and similar materials.

zero waste

low noise

long lifespan

easy to clean

Film/Sheet Plastic Recycling

Shredder Machine

The Film/Sheet Plastic Recycling Shredder is ideal for grinding various films and sheets, including PP, PE, PVC, PS, GPPS, PMMA. With versatile capabilities, this shredder provides an efficient solution for recycling different types of plastic materials. Its design is tailored to handle the specific characteristics of films and sheets, ensuring effective processing. Whether dealing with PP, PE, PVC, PS, GPPS, or PMMA, this machine contributes to sustainable practices by enabling the recycling of plastic films and sheets.

zero waste

low noise

long lifespan

Easy to clean

Powerful Plastic Crusher

Machine

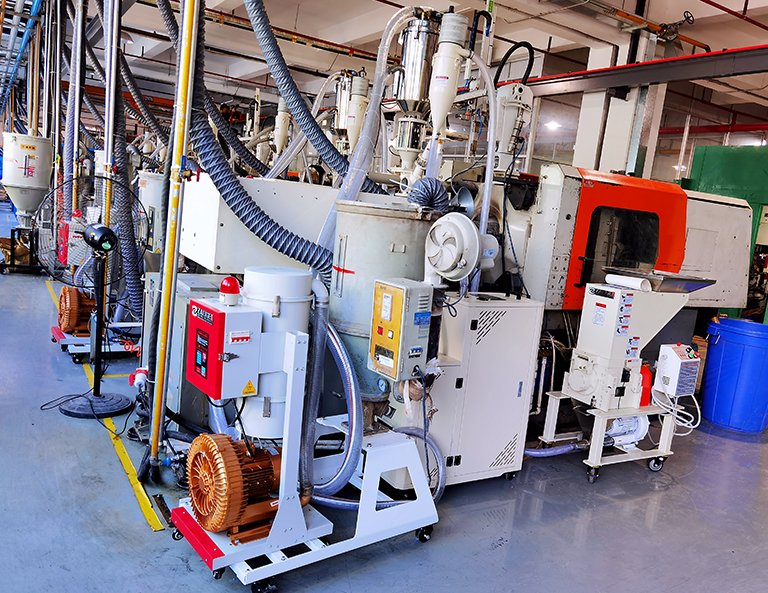

The Powerful Plastic Crusher series offers a wide range of applications and is primarily designed for the crushing of various types of soft and hard plastics. This versatile machine is capable of breaking down plastic materials of different shapes and sizes into granules, making it easier for recycling and reuse purposes.Whether it's PVC, PP, PE, TPR, or other plastic materials, the Powerful Plastic Crusher effectively reduces them to smaller particles, ensuring efficient handling and processing.

zero waste

noise-free

Easy to clean

long lifespan

We Grows with You !

ZAOGE Intelligent Technology originated from Taiwan Wanmeng Machinery, which was established in 1977. For more than 46 years, it has been focusing on the research, development, production and sales of high-quality, high-performance rubber and plastic environmental protection automation equipment.

The company has advanced mechanical processing equipment and assembly workshops. The main products include instant crushing system for various plastic nozzle materials, rubber and plastic environmental protection granulation equipment, and peripheral auxiliary equipment for injection molding, etc. .

We are committed to promoting the all-round development of the rubber and plastic industry towards high efficiency, energy saving and environmental protection, and giving new life to rubber and plastic!

ZAOGE intelligent technology—-use ingenuity to make rubber and plastic environmental protection and return to the beauty of nature!

SOLUTION

One-stop service to help you surpass competitors.

WHY CHOOSE US

Rubber and plastic environmental protection equipment, promoting low-carbon and efficient utilization of rubber and plastic.

R&D design

Chinese high-tech enterprise with a young and experienced professional R&D team, capable of customizing non-standard plastic crushing systems, plastic pelletizing systems, and more.

ZAOGE shredder offers specialized solutions for your specific application – helping you to increase productivity and added value, streamline processes, expand your service offerings, and become more profitable.

Our process standards are high, quality control is strict, meeting requirements, exceeding expectations. We have an exclusive service team providing lifelong service, ensuring worry-free usage.

In overseas markets, with highly competitive products and a market-oriented innovation system, Zaoge shredder has established a mature marketing network in many countries and regions around the world.

STAY CONNECTED

ZAOGE– 46years dedicated to one thing: utilize rubber and plastic, return to the beauty of nature.

Crafting Products with Integrity, Building Brands with Morality.

BRAND ASSURANCE

Doubts about the effectiveness?

Free inquiry.

Environmental standards not met?

Direct return.

Price difference?

Refund the difference

Quality issues?

eturn for redo

Service Process

No boasting, no deception; Embracing craftsmanship, seeking only the truth; Benefiting the environment, protecting the Earth.

Both parties engage in communication to understand the requirements and develop a reasonable technical solution that meets the specifications, functional features, and other detailed information.

Based on the technical solution, provide a detailed quotation and sign a sales contract with the customer after reaching an agreement, clearly defining the rights and responsibilities of both parties.

According to the agreement in the contract, production of the machinery and equipment begins, while maintaining communication with the customer to ensure that the equipment meets their requirements and is delivered on time. After production is complete, debugging and quality inspections are conducted to ensure that the equipment’s performance meets and exceeds the standards.

Assisting customers in arranging equipment transportation and logistics matters, providing necessary export documents and procedures to ensure smooth export and delivery of the equipment to the customer’s site.

Depending on the situation, we provide equipment installation guidance and operation training (online or offline) to ensure that customers can operate and maintain the equipment correctly. We also offer long-term, high-quality services, including technical consultation, spare parts supply, and repairs, to ensure the continuous and worry-free operation of the equipment.

ZAOGE --- Based in China, Eyes on the World

ZAOGE Plastic Shredder pursues its goal of serving you betterAS OF12/31/2023,THENUMBER OF PATENTSIS212

Frequently asked questions

ZAOGE shredder is your state-of-the-art shredder partner with expertise in shredder solutions for various industrial sectors and a customer-focused approach, providing innovative technology and outstanding support.

We are a Manufacturer located in Dongguan, China. Specialized in, it has been focusing on the research, development, production, and sales of high-quality, high-performance rubber and plastic environmental protection automation equipment. for more than 43 years, have thousands of customer cases, welcome for factory inspection.

Our minimum order quantity (MOQ) depends on the specific product line and customization requirements. Please reach out to our product specialists for detailed information regarding the MOQ for the product you are interested in. Alternatively you may check our list of MOQs here.

We strive to accommodate orders of various sizes to meet our customers diverse needs so don’t hesitate to contact us!

Yes, we provide Non-standard customization service. We have a professional R&D team and production equipment, and can design and manufacture products according to customer needs.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and

(2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

![]() Have other questions for us? Ask our experts directly!

Have other questions for us? Ask our experts directly!

ORTUNE GLOBAL 500 CERTIFICATION

Rubber products produced using the ZAOGE Rubber Environmentalutlization System are sold in over 100 countries worldwide